Rock Tumbler Grit

We use these grits for all of our own tumbling

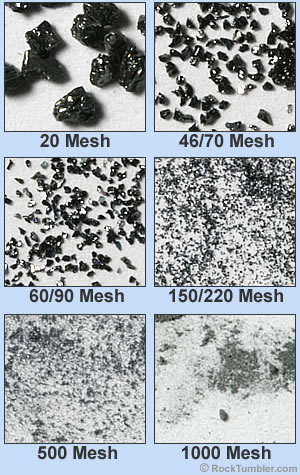

"Rock tumbler grit", also known as "rock polishing grit", is a silicon carbide powder that is much harder than the types of rocks that are commonly polished in a rock tumbler. If it is tumbled in a barrel with rocks and water the abrasion caused by the grit particles rounds the sharp edges off of the rocks. We use about two level tablespoons of grit per pound of rock in a rotary tumbler and 1/2 tablespoon of grit per pound of rock in a vibratory tumbler.

Individual Grits

Coarse Rock Tumbler Grit (60/90 Silicon Carbide)

60/90 Grit

Step 1 (Rotary)

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Medium Rock Tumbler Grit (150/220 Silicon Carbide)

150/220 Grit

Step 2 (Rotary)

Step 1 (Vibratory)

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Fine Rock Tumbler Grit (500F Silicon Carbide)

Also known as "pre-polish"

500F Grit

Step 3 (rotary)

Step 2 (vibratory)

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

What does the "F" mean? See questions and answers about grit at the bottom of this page.

Measuring Spoon - One Tablespoon

Rotary Grit Kits

Four-Step Rock Tumbler Grit Kits for Rotary Tumblers

Four Step Grit KitSave $49.96! Buying a large grit kit will save you $49.96 over the cost of buying five standard grit kits. Save $14.97 over the cost of buying the grits and polish separately. Your shipping costs will also be lower. In our opinion, this is the best deal on our website! |

Large Grit Kits

contain 5 pounds of coarse, medium and fine grit plus 2.5 pounds of TXP polish. Double bagged within corrugated boxes.

Standard Grit Kits

have 1 pound of coarse, medium and fine grit plus 8 ounces of TXP polish. This is enough supplies to tumble up to four three-pound barrels of rocks.

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Single-Use Rock Tumbler Grit Kits for 3-Pound Tumbler Barrels

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Vibratory Grit Kit

THREE-Step Rock Tumbler Grit Kit for Vibratory Tumblers

Save $61.96! Buying the large vibratory grit bundle will save you $61.96 over the cost of buying five standard vibratory kits. Your shipping costs will also be lower. |

Standard Vibratory Kit

-- This kit contains two pounds of medium grit (150/220), one pound of fine grit (500F), and one-half pound of #61 Rapid Polish (a sub micron aluminum oxide polish). This is enough grit and polish to process many pounds of rocks. More Information.

Large Vibratory Grit Bundle

-- If you do a lot of vibtatory tumbling, here's your opportunity to save money with our Large Vibratory Grit Bundle. It contains ten pounds of medium grit (150/220), five pounds of fine grit (500F) and 2.5 pounds of #61 Rapid Polish (a sub micron aluminum oxide polish).

This kit contains 5x as much grit and polish as the standard kit for about 3.3x the cost. More Information. Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Extra Coarse and Ultra Fine Grit

These are grit sizes that we don't normally use in our own rock tumbling. However, we do use them occasionally, and some people use them on a regular basis.

Extra Coarse Grit (46/70 Mesh)

46/70 Grit

We did a few experiments to test the effectiveness of extra coarse grit. You can read about the results at the bottom of this page and in our article about extra coarse grit.

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Ultra Fine Rock Tumbler Grit (1000 Silicon Carbide)

1000 Grit

Pre-Polish

Caution: Do not dispose of used grit, polish or rock slurry down a drain.

Common Questions About Rock Tumbler Grit

Q: Can I Use Sand Instead of Rock Tumbler Grit?

Yes, you can if you want, but we bet that you will change your mind after the first batch of rocks. Here are the advantages of using rock tumbler grit (more formally known as "silicon carbide grit")...

1) Silicon carbide grit is very hard. It is much harder than the rocks that most people tumble. On the Mohs Hardness scale silicon carbide has a hardness of 9 to 9.5 while commonly-tumbled rocks such as jasper, agate, quartz and petrified wood have a Mohs Hardness of about 7. This means that silicon carbide grit can easily abrade the rocks that most people tumble. However, most beach, river, and wind-blown sands are composed of quartz, which has the same hardness as the rocks that most people tumble. Since it has an equal hardness, it will be ineffective at abrading them in the tumbler barrel.

2) Quality silicon carbide grit usually occurs in angular particles. That means they have sharp points and edges that facilitate abrasion on the rocks while tumbling occurs. However, most beach, river, and wind-blown sands have rounded particles, which makes them ineffective at abrading the rocks that you are hoping that they will grind.

3) Rock tumbler grit can easily be purchased in sizes that are perfect for rock tumbling. To duplicate the coarse, medium and fine grits used in rock tumbling you would have to purchase a set of sieves, find sand of various particle sizes and separate it into the grit sizes needed for rock tumbling. We are willing to bet that you will burn more gasoline and time chasing these special particle sizes of sand than you would spend buying some good grit. It isn't that expensive.

In summary, you can use sand instead of rock tumbler grit. But, if you do that, the sand may not be effective at cutting the rocks because it has the same hardness as the rocks and it usually occurs in rounded grains. You will probably waste a lot of time and electricity trying to save money using sand instead of rock tumbler grit. We have an article titled "Can I Use Sand Instead of Grit?" that explains all of this in much more detail.

Q: Would You Explain the Grit Sizes Used for Rock Tumbler Grit?

Lots of people ask about that. We have an article that describes the man-made material known as "rock tumbler grit" and a chart that explains the various grit sizes. The title of the article is "What is Silicon Carbide Grit?". The Wikipedia article for "silicon carbide" also has a lot of good information.

Q: Can I Recycle Rock Tumbler Grit?

The practical answer to this question is "no," but we will explain the "yes" part in a few sentences. When you place your loaded barrel on your rock tumbler and turn it on, the particles of grit will become caught between the tumbling rocks in the barrel and each time that occurs the grit places a small scratch in the surface of the rock. Over the hours and days of continuous tumbling this happens millions or billions of times.

All of this abrasion wears the sharp edges off of the rocks and smooths their surface. It also does some damage to the grit. The grit particles also break and wear down during the tumbling process. So at the end of a week of tumbling your coarse grit will be in a much larger number of particles and each of those particles will be smaller than what you started with.

If you had a screen with a very fine mesh, you could pour the muddy liquid in your tumbler barrel through it and wash all of the mud through. A lot of the granules that remain on that screen would probably be small particles of silicon carbide grit. However, it would be "spent" silicon carbide grit and the value of that grit is probably less than the value of the time that you will spend and the soap and water you will spend cleaning-up after your recycling work.

So, even though you "can" recycle a little bit of grit, we don't know anyone who has tried to do it more than once. :-)

If you see grains of grit in the barrel after tumbling, instead of trying to recycle it, consider one of these two actions. A) Run the tumbler a few more days to wear out that grit. It will probably improve the roundness and smoothness of your stones. (You might also try using a little less grit if the rocks that you are tumbling have a Mohs Hardness of less than about 6 or 7. These rocks don't wear out the grit as rapidly.) B) Consider that your barrel might have been too full. If you are filling your barrel more than about 2/3 full, your rocks might not have enough room in the barrel to tumble properly. So, the barrel is going round and round and the rocks are in that barrel locked in a big mass. Reducing the amount of rocks by just a little will give them more space to tumble and give your grit a chance to do its job.

Q: Why Don't You Use Extra Coarse for Extra Fast Grinding?

We used to think that extra coarse grit would be a great idea.

Here's a story..... We had some beautiful big pieces of Ohio Flint and they were REALLY REALLY hard. We tumbled them for a full month in 60/90 grit silicon carbide and added 50% extra grit to sustain grinding the entire month. (We also added extra water to dilute a month's worth of mud!) At the end, the pieces had worn down a bit but they still needed a lot more tumbling to get the shape that we wanted.

So we bought some 20 mesh grit with the idea that it would tear up that flint quickly. Heh!

We added the normal amount of 20 grit and ran the tumbler for a month. At the end of the month we opened the barrel. Lots of that 20 grit had survived! Almost all of it had survived. It was almost the same particle size as when we started - it was only slightly smaller. And the flint was not rounded as well as if we had used our normal 60/90 grit. It was not a lot better than when we started.

We have used 20 grit for several other materials with the same results. Why isn't it effective??

When you use 20 grit the particles are really big, but there are very few of them to do the grinding. However, when you use 60/90 grit there are a LOT more abrasive granules in the barrel, and they grind away everywhere.

We have also experimented with 54 mesh grit. The particles of 54 grit are much larger than the blend between 60/90, and it is large enough to do more aggressive cutting. However, there are still not nearly as many granules in the barrel to do the work of cutting.

In summary, whoever first decided to use 60/90 grit in a rock tumbler knew what they were doing. If you want to read the results of our experiments with extra coarse grit, you can find an article here. If you don't believe us and want to try some 20 grit yourself, click this link to add two pounds to your shopping cart for $9.99.

Q: Would I Get a Better Polish With a 1000 Grit Step?

We use 500 or 600 grit as the final grinding step before polishing 99% of the time. We get great results and do not think that the extra time and expense of a 1000 grit step is needed. We might use a 1000 grit step if we were competing in the Worldwide Rock Tumbling Contest. We would use it just to be sure that our rocks were extra ready for the polishing step.

But, otherwise, the only time we use 1000 grit is when we tumble a very soft material such as fluorite or calcite. We use 1000 grit as the last grinding step in a vibratory tumbler. We then do the polishing step dry, in a vibratory tumbler, filled with crushed corn cob media that has been treated with TXP Polish or Rapid Polish. The entire bowl is filled with corn cob, we add about three level tablespoons of polish per pound of corn cob, and we only add a few pieces of the rock we are trying to polish.

One-thousand grit is really expensive. Unless you are polishing rocks for the Queen, or are preparing for dry polishing, we don't think you need to use an ultrafine grit step.

Q: My Grit Is Labeled 500F. What Does the F Mean?

When you see a grit number followed by the letter "F" - that means that the grit has a finer (smaller) grit size than the number. For example: 500F means that the grit is finer than 500 grit. "F" means "finer".

Happy Tumbling