Ceramic Media Can Improve Your Tumbled Stones

What Is Rock Tumbling Media?

Rock tumbling media is a rounded or cylindrical material added to the tumbler barrel to improve the results of your tumbling. Its rounded shape improves the tumbling action. Its presence between the tumbling stones facilitates abrasion on all surfaces of the stones. The smoother tumbling action helps to prevent chipping and bruising of the tumbled stones.

Ceramic Pellet Media

Most media used in rock tumbling today is a kiln-fired ceramic pellet media that has a hardness of 7+ on the Mohs Hardness Scale and an excellent tenacity. It is extremely durable, reusable, easy to clean, and will last through many batches of tumbled stones. We use ceramic pellet media in most of our rotary and vibratory tumbling.

Plastic Pellet Media

Plastic pellets were the most popular tumbling media from the 1960s through the 1990s. They were used to cushion the stones and reduce bruising caused during tumbling.

Today most people use ceramic media, but some have used plastic pellets for decades and still prefer them for rotary tumbling. Ceramic cylinders smooth the tumbling action and this results in less bruising of the stones. Ceramic media is also hard and more effective at grinding and shaping stones.

Should I Use Ceramic Media or Plastic Media?Here's the Verdict of Our Customers:Today we sell over 10 times more ceramic media than plastic media.(Determined on the basis of weight.) |

When ceramic media became popular in the early 2000s, most people who tried it stopped using plastic media - because ceramics were more convenient. When using plastic pellets, the pellets can only be used with one size of grit - because tiny particles of grit become embedded within them. When using ceramic pellets, the rock mud and the grit rinse right off of the stones between tumbling steps. Here is the verdict of our customers: Today we sell over 10 times more ceramic media than plastic media.

Benefits of Using Ceramic Media:

When properly used, ceramic tumbling media can improve your tumbled stones. Here are several benefits from using ceramic cylinder media:

1) Cushioning: The media reduces the impact energy between the stones in the barrel.

2) Particle Size Balancing: Add small particles to a load of large rocks.

3) Filler: Get the barrel up to operating capacity.

4) Improve Tumbling Action: Smoothes the tumbling action of the rocks in the barrel tumble better.

5) Deliver Grit to All Rock Surfaces: Facilitates grinding and polishing.

Now that you understand the benefits of using ceramic tumbling media you still need to determine... Which size should you use? How much should you use? Below are recommendations on how you can achieve the benefits listed above.

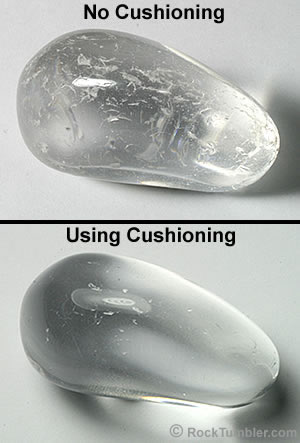

The top image shows the piece after being tumbled without proper cushioning. The stone has numerous chips and bruises. This damage was cause by hard impacts with other stones in the barrel.

The bottom image shows it after being re-tumbled using ceramic media as cushioning. You can see how much less chipping and bruising are on the stone.

Cushioning:

Have you ever tumbled a batch of rough only to open the barrel after the polishing step and notice little white fractures or chipping around the edges of your stones?

Those marks on the stone are called "bruises" and they are a result of the stones banging against one another in the tumbler with enough force to cause damage.

Most bruises result from two things:

1) a tumbler that is too fast for the durability of your stones (most tumblers are too fast for almost any type of stone except jasper, agate and other varieties of chalcedony), and,

2) large stones being banged against one another in the tumbler. Cushioning your stones will reduce, and in many cases, eliminate this problem.

How does media provide cushioning and stop your stones from bruising each other? Media in the barrel will keep the stones from hitting one another as often as they do when there is no media. The media will also reduce the impact force that the stones have upon one another when they do collide.

Think of a child jumping into a ball pit like we used to see at McDonald's. If there were no balls in the pit the child would have a high energy impact with the floor. However, with the balls in the pit, much of the impact energy is absorbed by the balls.

The initial energy from his fall starts to be absorbed by the first balls his body touches. That energy is then transferred with less force to all of the balls that they touch. Then with even less force the energy is transferred to all of the balls that they touch. This continues until all of the energy has been absorbed through less and less forceful impacts between the balls.

All of this energy absorption keeps the child from hitting the floor or if they do hit the floor it is with very little force. Using ceramic media in the barrel can have the same effect on the rocks in the barrel.

What Types of Rocks Need Cushioning?

Two types of materials require cushioning:

1) those that bruise or chip easily; and,

2) those that break easily by cleavage.

Materials that bruise or chip easily include: obsidian, glass and crystalline quartz. (Banded amethyst, rose quartz, rock crystal, aventurine, and tiger's eye are common varieties of crystalline quartz.) These materials can be chipped or bruised by impacting with one another in the barrel. Adding media for cushioning can reduce this damage.

Materials that cleave easily include: fluorite, topaz, moonstone, amazonite, labradorite and orthoclase. Many people avoid tumbling these materials because they are difficult to tumble with good results. Adding media for cushioning can solve that problem.

We use at least 50% media in the barrel to properly cushion especially fragile tumbling rough such as obsidian or glass. Small ceramic media works best to cushion the material. However, we usually use a mix of large and small media for cushioning and get good results.

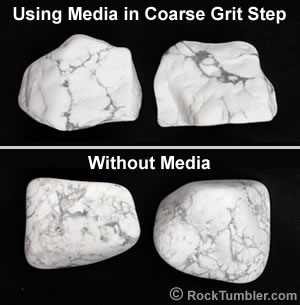

The bottom illustration shows how media can fill the spaces between the stones. Filling in those spaces also creates many more contact points on the rough. The stones in the bottom illustration will shape much faster and are less likely to chip or bruise.

Particle Size Balancing:

What is particle size balancing? Particle size balancing is making sure that you have a range of different sized material in the barrel. If the rough in the barrel are all large pieces there won't be many points of rock to rock contact as they tumble. Grit does its job when it is caught between the stones and the media. The pressure of that contact enables the particles of grit to abrade and smooth the stones.

Imagine bowling balls in a box, there are only a few points where they touch each other. Now if you put some golf balls in that box you have significantly increased the number of contact points on the bowling balls and filled much of the empty space between them. Adding marbles would fill in even more of the empty spaces in the box and maximize the points of contact against the bowling balls. This shows how using a range of particle sizes in the barrel increases the number of contact points where the shaping and smoothing of the stone occurs.

The best way to get a balanced load in the barrel is by using a range of smaller pieces of rough. If you don't have smaller pieces of rough ceramic media should be used. If you are using ceramic media for the first time we suggest getting both small and large because having a range of sizes in the barrel works best.

Improve Tumbling Action in the Barrel:

If you have rough with lots of flat pieces (such as trim-saw slabs) or lots of very angular pieces, they might slide in the barrel instead of tumbling. Adding ceramic cylinders will help get those stones tumbling. Ceramic cylinders act like roller bearings in the tumbler barrel. They get between flat and angular pieces of rough and increase their motion. A mix of ceramic media sizes works best.

Filler:

The most important use of ceramic media as filler is in replacing the volume of rock lost during the coarse and medium grit steps of the tumbling process.

During the coarse grit step between 10% and 30% of the rock volume in your barrel is lost to grinding. It is worn away and becomes the rock mud that you see in the barrel after tumbling a batch of rocks.

To maintain a good tumbling action and to keep your barrel up to the recommended tumbling volume of about 2/3 full, adding ceramic media is recommended. We add enough ceramic media to bring the barrel up to about 2/3 full.

Less rock volume is lost during the medium grit step, but it is still important to add ceramic media to keep your barrel at the recommended tumbling level.

Replacement of rock volume with ceramic media is important in both rotary and vibratory tumblers. The ceramic media helps give your rocks a smoother ride during the fine grit and polishing steps. Without the addition of media, the rocks will receive a rougher ride that might cause chipping and bruising.

The only situations where we would use more than about 10% media during the coarse grit step of rotary tumbling are: (A) when we have a barrel full of large material with nothing filling the spaces between the rocks, then we might use up to about 20% media to improve the tumbling action; and, (B) when the rocks already have a nicely rounded shape and only surface smoothing is needed.)

How Long Will Ceramic Media Last?

Ceramic tumbler media has a hardness of about 7+. It is harder than almost all of the most commonly tumbled rocks such as agate and jasper. Small media will last a few tumbling cycles when used in all steps of the tumbling process. Large ceramic media will last much longer and eventually turn into small media.

How Do We Use Media?

For the most durable materials (agate, jasper and other varieties of chalcedony) we often use no media (or at most 10% media) in the coarse grit step. Then, as we load the barrel for the medium grit step, we will add just enough media to bring the level of material in the barrel up to about 2/3 full. That's all. We do not add more media.

For less durable materials, we use between 10% and 50% ceramic cylinder media every time we run a tumbler. We believe that a mix of large and small media works best. Tiny tumbled stones also enter into our media plan.

After each batch of rocks is polished, we separate media from tumbled stones using a classifier. The tumbled stones do not pass through the classifier, but all media and a small number of tiny tumbled stones fall through into Our Media Bucket. This bucket always contains polished media in a range of sizes ready for use in tumbling. We keep it supplied by frequently adding a small amount of new large media to the coarse grit step of each batch of rocks that we tumble.

If you do a lot of tumbling or simply want to save time, we suggest that you read the Our Media Bucket article.

Breaking in New Media

Brand-new media will have some surface roughness that remains after the manufacturing process. If you look closely at brand-new media, you will see roughness around the ends of the pieces. If you add brand-new media to a batch of rocks during the coarse or medium grit step, there is no need to worry about this roughness. It will be smoothed during your normal tumbling.

However, adding brand-new media to a batch of rocks at the beginning of the fine grit or polishing step might produce scratches on your stones. When adding media at this point in the process, it should be media that has been previously tumbled and all edge roughness removed. Preferably, it should be media that was polished in a previous batch of rocks. If you don't have that, simply run the media for a few days in medium grit, followed by a few days in fine grit, and it will be ready to use.

Plastic Pellets:

Plastic pellets have a long history of use for cushioning in rotary tumblers and many people still use them. Note: We do not recommend them for use in vibratory tumblers.

We stopped using plastic pellets years ago after we tried ceramic media. We found that ceramic media is just as effective as plastic for cushioning. Here are a few other reasons why we switched to ceramic media for all of our tumbling.

Plastic pellets...

1) Are difficult to separate from the rocks and gather after rinsing.

2) Are tough to get clean and dry before storing.

3) Cannot be reused in a finer grit step because grit embedded in them can contaminate the next steps.

4) Must be stored in separate containers according to the grit they were used in.

5) Do not help much during grinding because they are soft.

Not All Ceramic Media Works in Rock Tumbling

Ceramic media is sold for a wide variety of purposes and most of it contains embedded abrasive granules. If you use ceramic media with embedded abrasive granules during the polish step they will scratch the stones and ruin your polish. All of the ceramic media that we sell is smooth and does not contain any abrasives.

If you are going to buy ceramic media you need to either really know what you are doing, or only purchase ceramic media from a rock tumbling site that tests their products before they sell them. We test everything that we sell ourselves - and we use the same ceramic media that we sell every day in our own tumbling.

Happy Tumbling!

RockTumbler.com Authors

|

Hobart M. King has decades of rock tumbling experience and writes most of the articles on RockTumbler.com. He has a PhD in geology and is a GIA graduate gemologist. He also writes the articles about rocks, minerals and gems on Geology.com. |