Thumler's MP-1 Questions and Answers

What Is the Thumler's MP-1 Rock Tumbler?

Thumler's MP-1 is a single barrel rotary rock tumbler. It is a beginner's grade tumbler with a small-capacity rubber barrel. It is perfect for the beginner or for running small test batches.

The small capacity and low purchase price makes it economical for someone who is just getting into the rock tumbling hobby. The Thumler's MP-1 is sold as a kit that includes the machine, the rough and grit needed to run the first batch of rocks, and a small jewelry findings kit.

Below we will address the most common customer questions about this tumbler.

Where Should I Run My MP-1 Tumbler?

Operate this tumbler in a location that does not get too hot or too cold. If the tumbler motor gets too hot it will stop. The motor is air cooled so operation in direct sunlight or in a confined space is not recommended.

Running a tumbler in below-freezing temperatures will cause problems. The water and slurry in the barrel can freeze, pop the lid off of the barrel and make a huge frozen mess. We have a great article with more considerations when choosing where to operate a tumbler.

How Full Should the Barrel Be?

Whenever you are operating a rotary rock tumbler, the barrel should be 1/2 to 3/4 full with material. The MP-1 tumbler's barrel will take about 1 pound of material to get it to the recommended capacity.

Please watch the accompanying video. Or, please check out this video and article to know why the amount of material in the barrel is so important.

What Size Rocks Can Be Tumbled?

We recommend pieces no larger than 1 1/4 inches for the MP-1 barrel. The height of the usable space in the barrel is a little over 2 1/2 inches. So, we do not put in material that is larger than 1/2 of the smallest dimension of a barrel. It is best to only place a couple large pieces in the barrel. Too many large pieces will interfere with the tumbling action.

We have an article titled: What Size Rocks Should Be Used in a Tumbler? It explains, in detail, the sizes of rocks that you can consider tumbling in a variety of tumblers.

We oil the bearings while the shafts are mounted on the tumbler. We apply just one drop of oil directly onto the drive shaft between the bearing and the plastic guide. We then turn the drive shaft to help the oil flow into the bearing. We then wipe off any excess oil with a soft cloth. (You can see a diagram with the names of all parts at the bottom of this page.)

On the idler shaft (shown above), some oil will flow under the nylon guide. That is OK, because the guide can also be a source of squeaking. We also oil the bearings on the drive shaft (which does not have nylon guides). All four bearings on an MP-1 tumbler should be oiled once a month - or after each batch of rocks.

On the idler shaft (shown above), some oil will flow under the nylon guide. That is OK, because the guide can also be a source of squeaking. We also oil the bearings on the drive shaft (which does not have nylon guides). All four bearings on an MP-1 tumbler should be oiled once a month - or after each batch of rocks.

How Do I Stop My Tumbler From Squeaking?

Oiling the bearings on a Thumler's MP-1 tumbler will stop the squeaking noise most of the time. Each of the four bearings should be oiled once a month (or after each batch of rocks). Apply just one drop of oil on each bearing. Wipe off any excess oil with a soft rag.

We use SAE20 motor oil or a light machine oil. Both of these (or a suitable substitute) are available at any hardware store).

If the bearings are dirty, remove them and clean them in water with a few drops of mild dish detergent (we use Palmolive or Dawn). Rinse and dry them thoroughly before adding new oil.

Cleaning and oiling the bearings will keep the tumbler running smooth and prevent the bearings from squeaking. We have more information about how to oil the tumbler bearings here.

Does the MP-1 Motor Need to Be Oiled?

No, this motor does not require oil to maintain smooth operation. It is located within the plastic housing on the base which helps protect it from dust and damage.

Should the Barrel Rub Against the Guide?

Yes, the barrel tends to "walk" to the left or right, and the barrel guides are there to keep it on the rollers. It is important to watch which way the barrel "walks". You want the bottom of the barrel facing the barrel guide that barrel is "walking" towards. The next section will explain why.

Here we see some rubber particles on the tumbler base. This is normal. However, be sure to place the bottom end of the barrel against the guide that is causing wear.

Why are There Rubber Particles on the Base?

As mentioned above, the barrel will often be rubbing against a barrel guide. As they rub against one another, the contact between them will cause the barrel to shed some particles. It is common and should not be cause for concern. The amount removed will decrease as the barrel becomes shaped to ride smoothly against the guide. A new barrel or new barrel guide can cause this to happen.

This is why you want to pay attention to which way the barrel "walks". If the lid side is rubbing against the guide, flip the barrel so that the bottom will be rubbing against the guide instead. You do not want the lip that holds the retainer ring in place to get worn down. If it does, the lid retainer ring will not hold the lid in place, causing the barrel to leak or the lid to pop off.

The Motor is Running but the Barrel is Not Turning?

A worn belt, slipping belt or stuck bearings can cause this to happen.

Second, clean the belt and pulleys. Dirt or oil on the belt or pulleys can cause it to slip. With the machine turned off, remove the belt. Use Dawn dishwashing liquid or similar detergent to clean off the pulleys and belt. A cotton swab works well to clean the grooves of the pulleys. Thoroughly dry them with a cloth after cleaning. Any soap residue left can allow the belt to continue slipping.

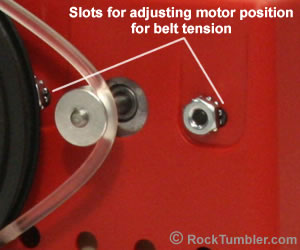

As a last resort you can adjust the tension on the MP-1 tumbler belt. Loosen the motor mount nuts and slide the motor away from the drive shaft. There is not much room for adjusting but it may be enough to keep the belt from slipping. NOTE: If this worked you may want to buy a spare belt to have for the next time.

If none of the above steps solved the problem, then you will need a new belt.

Why is My Barrel Leaking?

There are many things that can cause the barrel to leak, such as a damaged or worn lid, stretched out retainer ring, or grit particles on the sealing surfaces. We have an article to help diagnose the possible cause here.

Thumler's MP-1 Parts Diagram

1) Rubber Barrel - The rubber barrel helps with quiet operation and is gentle on the stones.

2) Plastic Barrel Lid

3) Barrel Retainer Ring - Holds the lid in place to create the watertight seal.

4) Motor (in housing)

5) Motor Pulley

6) Tumbler Belt - Turns the drive shaft which turns the barrel.

7) Drive Shaft - Has two shortened rubber rollers, drive pulley and two bearings. This shaft makes the barrel rotate.

8) Idler Shaft - Has two shortened nylon rollers, two barrel guides, two bearings and two shaft retainer clips.

9) Bearings - Both shafts have a bearing on each end. The bearings hold the shafts on the base. Oil them monthly to maintain smooth and quiet operation.

10) Rubber Rollers - Located on the drive shaft to give traction to the barrel and cause it to rotate.

11) Nylon Rollers - Located on the idler shaft to reduce friction on the barrel for smooth rotation.

12) Barrel Guides - Keep the barrels on the rollers.

13) Shaft Retainer Clips - Hold the barrel guides and nylon rollers in place on the idler shaft.

Happy Tumbling!

RockTumbler.com Authors

|

Hobart M. King has decades of rock tumbling experience and writes most of the articles on RockTumbler.com. He has a PhD in geology and is a GIA graduate gemologist. He also writes the articles about rocks, minerals and gems on Geology.com. |