Oiling A Thumler's Rotary Rock Tumbler

Oiling your tumbler is the best way to stop squeaking and prevent wear.

It is also the best way to help your tumbler's motor last a long time.

We use 3-IN-ONE oil to lubricate the bearings and the motors of our tumblers. It is sold in convenient dispenser bottle for precise application. SAE 20 motor oil or multipurpose oil will do a good job.

Safety First!Please unplug your tumbler before inspecting it or doing maintenance. |

Oiling Your Tumbler Is Easy

Oiling your rock tumbler is a very easy job. Most Thumler's Tumblers have two parts that require lubrication: 1) their bearings, and, 2) their motor.

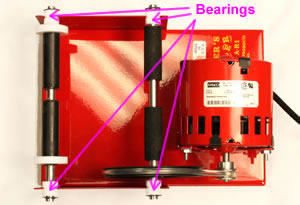

Bearings: All Thumler's rotary rock tumblers have four bearings that must be kept clean and oiled. Regular cleaning and lubrication will keep the bearings from squeaking and prolongs their life. Oiling helps the bearings run smoothly and reduces the load on the motor. We show you how to do this easy job below.

Motors: Most Thumler's Tumblers rotary tumblers have Fasco motors that require oiling about once every month (or after each batch of rocks has been processed). In the article below we have photos to help you determine if your motor requires oiling. If it must be oiled, all it takes is one drop of oil in each oil port after each month of operation, or after you finish tumbling a batch of rocks. Oiling the motor is an easy job.

All four bearings should be cleaned and oiled once a month. This photo shows the location of the bearings on a Thumler's tumbler base.

To oil the bearings, place a drop of oil onto the shaft next to the bearing and manually turn and slide the shaft back and forth to ensure that oil gets between the bearing and the shaft. Wipe off any excess oil.

Oiling the Bearings

Is your Thumler's Tumbler squeaking? If it is, most likely your bearings need oil. There are four plastic bearings: one on each end of the drive shaft, and one on each end of the idler shaft (see the accompanying photo).

These bearings should be cleaned and oiled after each month of operation (or after every batch of rocks has been completed). The bearings will last longer and operate quietly if they are lubricated and kept clean.

Before oiling, use a paper towel or a soft rag to wipe any excess oil and/or dirt from the part of the drive shaft that contacts the bearings. Grab the shaft near each bearing with a rag and rotate the shaft with your free hand to remove any excess oil and dirt.

This cleaning is very important. If the excess oil is not wiped off it will attract and hold dust, dirt and grit. Grit in the bearings will ruin them and grind your drive or idler shaft.

One drop per month on each bearing is all that is needed.

PLEASE NOTE: Do not get oil on the drive belt, on the surface of the rubber rollers, or on the surface of the nylon rollers. If you accidentally get a drop of oil on these or other parts, wipe it off and clean that area with the corner of a soft cloth that has been dipped in soapy water (a mild dishwashing detergent like Palmolive or Dawn is perfect).

To oil the nylon rollers, place one drop of oil onto the shaft next to the roller and manually turn the roller to ensure that oil gets between the roller and the shaft. Wipe off any excess oil.

Oiling the Nylon Rollers

Oil the rollers? Are you sure?

Yes, but only on the idler shaft, and only if they are squeaking.

Occasionally a Thumler's rotary tumbler will develop a squeaky nylon roller. This is normal. The nylon rollers are the hard plastic rollers on the idler shaft. Their purpose is simply to facilitate the rolling of the barrel.

The idler shaft rollers are often loose and can turn independently of the shaft. Sometimes they will start making an annoying squeak when they turn on the shaft. This squeaking can be eliminated by applying one drop of oil on one side of the roller (see the accompanying photo).

Capillary action will help the oil flow under the roller, and turning the roller by hand will help distribute the oil throughout the underside of the roller. Wipe off any excess oil when you are finished.

This lubrication is normally not needed on a monthly schedule. It is best done on an "as-needed" basis.

PLEASE NOTE: The rollers on the drive shaft are made of a "grippy" rubber that enables them to turn the tumbler barrel. They do not need oil. If you accidentally get a drop of oil on the rubber drive shaft rollers, wipe it off and clean that area with the corner of a soft cloth that has been dipped in soapy water (a mild dishwashing detergent like Palmolive or Dawn is perfect).

Motor With Two Oil Ports: This motor has two oil ports and requires oiling. One drop of SAE 20 oil or multipurpose oil in each port after each month of operation (we add oil after each batch of rocks - which takes about one month or slightly longer). These motors were made by FASCO.

Looking Down Into the Oil Port: This is a close-up photo that allows you to see the silver metal channel that helps the oil to flow to the motor's drive shaft. This motor requires oiling.

NOTE: If you do not see the silver metal channel in the oil port, you may have a sealed bearing motor. Some Thumler's vibratory tumblers were made in a case that had unnecessary oil ports but no silver oil channels. Do not oil these motors.

NOTE: If you do not see the silver metal channel in the oil port, you may have a sealed bearing motor. Some Thumler's vibratory tumblers were made in a case that had unnecessary oil ports but no silver oil channels. Do not oil these motors.

Sealed Bearing Motor: This motor was lubricated and sealed at the factory. It does not have oil ports. It does not require oiling. These motors are made by P-TECH.

Does Your Motor Require Oiling?

Almost all Thumler's rotary tumblers have a Fasco motor that should be oiled about once per month. However, during the covid pandemic Fasco motors were not available and P-Tech motors with sealed bearings were used on some Thumler's rotary tumblers.

Motors that require oiling will have a Fasco label. These motors also have two oil ports - one on each end of the motor immediately above the drive shaft (see the accompanying photo).

To make sure that they are oil ports, look down into the port to see if there is a silver-color metal channel inside of it (see the accompanying photo).

Did You Find Oil Ports?

If you found oil ports with silver metal channels on a FASCO motor, then your motor requires oiling. Before you get your oil bottle (or can), this is a great time to make sure that your motor is clean. Get a clean dry cloth and wipe any dirt from your motor. Be careful how you wipe the motor. Be careful that you do not wipe dirt into the oil port or wipe dirt into the air vents.

Now, place one drop of SAE 20 oil or multipurpose oil in each oil port after each month of operation. (We oil our motors after each batch of rocks - which takes about one month or a little longer.) Wipe off any excess oil with a clean, soft, dry rag.

You Didn't Find Oil Ports?

If you didn't find oil ports, then your motor will look similar to the "Sealed Bearing Motor" in the accompanying photo. If your motor was made by P-TECH, it is a sealed bearing motor that does not require oiling.

Keep this motor clean. Operate it where it will not inhale dust and dirt, and it should last a long time.

Need More Help?

To help you further with making sure that you are oiling your Thumler's rotary tumbler properly, we have prepared a tumbler-by-tumbler summary below.Find Your Tumbler

Thumler's MP-1

Motor: MP-1 motors have sealed bearings and do not require oil.

Thumler's Model T

Motor: Model T motors have sealed bearings and do not require oil.

Thumler's A-R1

Motor: FASCO motors require oiling. P-TECH motors have factory-sealed bearings and do not require oiling.

Thumler's A-R2

Motor: FASCO motors require oiling. P-TECH motors have factory-sealed bearings and do not require oiling.

Thumler's Model T2

Motor: Model T2 motors have sealed bearings and do not require oiling.

Thumler's A-R6

Motor: FASCO motors require oiling. P-TECH motors have factory-sealed bearings and do not require oiling.

Thumler's A-R12

Motor: FASCO motors require oiling. P-TECH motors have factory-sealed bearings and do not require oiling.

Thumler's Model B

Motor: FASCO motors require oiling. P-TECH motors have factory-sealed bearings and do not require oiling.

We use 3-IN-ONE oil. You can buy it in this convenient dispenser bottle. It is SAE 20. The manufacturer says it "keeps small motors humming happily". We have it available for sale:

The Importance of Clean Operation!

Keeping the tumbler clean of excess oil is very important. Oil attracts and holds dust, dirt and grit. Dust and dirt can attract and hold moisture. Dust, dirt and grit on the bearings will cause excess wear. Moisture on metal parts will cause them to rust.

Be careful when applying oil. Oil will damage the soft parts of your tumbler such as the barrels, belt, and the rubber rollers on the drive shaft. If you accidentally get oil on any of these soft parts, clean it with a rag or paper towel that has been moistened with a gentle soap - such as Dawn dishwashing detergent.

Finally, if you notice that your tumbler is accumulating a lot of dust and dirt, it might be a good idea to find another location for your tumbling. Tumbler motors are air cooled. Operating them in a dusty, dirty environment will force them to inhale dirty air. That will significantly shorten the life of your motor. Dust and dirt accumulations in the tumbler can also become a fire hazard. Keep your tumbler and the area around it clean!

Happy Tumbling!

Following the lubrication and cleanliness tips above is easy and will help your tumbler run quietly and efficiently for a long time. Many of our customers have tumblers that have been in operation for decades of regular use. We still use a Thumler's Model A-R2 tumbler that was given to us as a Christmas gift in the 1960s.

RockTumbler.com Authors

|

Hobart M. King has decades of rock tumbling experience and writes most of the articles on RockTumbler.com. He has a PhD in geology and is a GIA graduate gemologist. He also writes the articles about rocks, minerals and gems on Geology.com. |