Thumler's UV-10 Vibratory Tumblers

The Difference Between Industrial and Standard

The Standard version is for light-duty work such as cleaning and polishing brass casings. The Industrial version is for heavy-duty work such as rock tumbling or deburring heavy metal parts. If you are looking to buy a Thumler's vibratory tumbler, you should know how to tell the two versions apart. This will ensure you get the one that can handle your needs.

In this photo you see an Industrial UV-10 (left) and a Standard UV-10 (right). If you have one of each version side by side, it is easy to see the differences. If you do not, it is important to know what to look for to ensure you are purchasing the proper machine.

What Do the Bowl Stripe Colors Mean?

While these bowls are similar in size and shape, they are not constructed the same. The color of the stripe on the bowl lets you know what the bowl was designed for.

The Industrial version has a blue stripe on the bowl. It is for wet tumbling which includes rock tumbling and metal deburring. The Industrial bowl is thicker and therefore more durable than the Standard bowl. You can use the blue-striped Industrial bowl for rock tumbling, metal deburring, or brass cleaning.

A yellow stripe indicates the bowl was designed for light-duty work, such as cleaning brass casings or jewelry parts using corn cob or walnut shell media. You should not use a yellow-striped bowl for rock tumbling. It is too thin and will wear out quickly.

NOTE: If you are purchasing a used UV-10 tumbler, look at more than the bowl stripe color. Both bowls will fit either machine. Look at other components of the tumbler to make sure you are getting the proper machine.

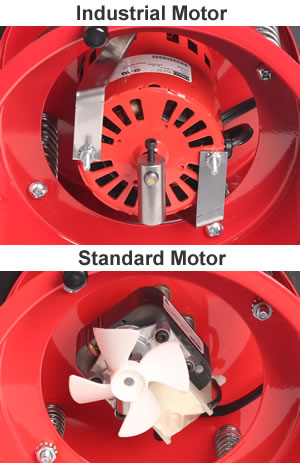

The Motors Are Different?

Absolutely. The Industrial and Standard UV-10 vibratory tumblers have different uses. For that reason their motors are very different.

Pre-2020 Tumbler Motors

Thumler's changed the motors used in the UV-10 tumbler in 2020. The description below and the accompanying photos are for tumblers manufactured prior to some time in 2020. (The date that you purchased your tumbler does not determine which motor you received. The important date is the date that it was manufactured.)

The Industrial UV-10 motor is a red Fasco motor with the cooling fan inside of its metal case. It is designed for large heavy loads and stress. The motor is held in place by four threaded rods that come out of the top of the motor and go through the base plate. There are also two brackets that attach to the tumbler base plate and the bottom of the motor. The mounting system keeps the motor snug to the base plate and stable - so when the motor spins the counterweight, all the vibrations go to the base plate. This creates a cyclonic motion of the rocks or brass that you have in the bowl. This motor should be lubricated about once a month (with SAE 20 oil or household machine oil) to keep it in good working order.

We have step-by-step instructions to guide you through replacing the Industrial UV-10 motor. It is not as difficult as it may appear. With just a few tools and supplies you can be up and running in a couple of hours.

The Standard version motor is a much smaller C-frame motor with an exposed fan. The counterweight that causes the machine to vibrate is on the shaft between the fan and motor. This motor attaches to the base plate with four bolts that go through the sides of the motor. The motor on the Standard version of the UV-10 does not need to be oiled.

Motors for 2020 and After

The description below and the accompanying photos are for tumblers manufactured sometime in 2020 and after. (The date that you purchased your tumbler does not determine which motor you received. The important date is the date that it was manufactured.)

In 2020, Thumlers started using C-frame motors manufactured by P-Tech in both the Industrial and Standard UV-10 tumblers. A big advantage of these motors for the UV-10 Industrial model is that these motors bolt directly to the frame of the tumbler. This eliminates the need for the complex bracket system on the Industrial model - which can be a challenge to replace. These motors also do not require lubrication.

Take a close look at the motors. You can clearly see that the motor for the Industrial UV-10 tumbler is a lot larger than the motor for the Standard UV-10 tumbler. The Industrial motor is rated at 1.75 amps, while the Standard motor is rated at 0.75 amps. The Industrial motor is a lot stronger than the Standard motor to handle the greater weight of a barrel full of rocks.

The Springs Are Different

The UV-10 Industrial springs are longer and made from thicker gauge metal. The Industrial version needs to be able to handle a lot more weight than the Standard. That weight creates a lot of stress on the springs when the machine is in operation, which is why they are larger.

Measuring the distance between the bottom lip of the base plate and the top of the base will let you know which machine it is. The Industrial version will have a gap of about 2 inches, and the Standard version will have a gap of about 1.25 inch.

Are Any Parts the Same?

Yes, there are several UV-10 tumbler parts that are the same for both versions. They both have the same feet, metal base, metal base plate, foam pads, center rod, wing nuts, and washers.

Operation and Maintenance Tips

Visit our Thumler's vibratory tumbler guide for tips on how to operate and maintain your Industrial UV-10 tumbler.

Happy Tumbling!

RockTumbler.com Authors

|

Hobart M. King has decades of rock tumbling experience and writes most of the articles on RockTumbler.com. He has a PhD in geology and is a GIA graduate gemologist. He also writes the articles about rocks, minerals and gems on Geology.com. |