Rounded Red Beach Stones

Mostly pink and red granite with a few other rock types.

This photo shows five pounds of red beach stones placed in a colander. Even though these beach stones were naturally rounded by stream and beach action, they have numerous blemishes that must be completely removed before they can be transformed into brightly polished stones. Click on the image for a larger view.

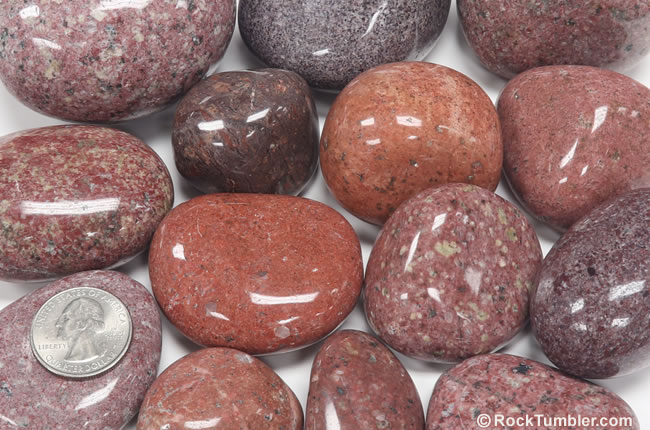

Here is a photo showing the same stones in the top photo after they were sprayed with water to show their approximate polished color (Doesn't a spritz of water improve their color?). A five-pound bag usually contains between 12 and 18 stones. Even though these stones are already rounded by stream and wave action, they still needed two to three weeks in a rotary tumbler to remove surface blemishes and be completely resurfaced. Click on the image for a larger view.

Here is a scatter of red beach stones that we recently polished. They spent two weeks tumbling in coarse grit in a Thumler's Model B rotary tumbler. The medium, fine and polishing steps were done in a Thumler's UV-18 vibratory tumbler. We vibrate these types of stones for three days in medium grit, two days in fine grit, and about three days in TXP polish. We were really happy with the results. Click on the image for a larger view.

Rounded Red Beach Stones

,

,  , and

, and  What do they mean?

What do they mean?

Size: Mostly 1-inch to 4-inch stones

-- Naturally rounded by wave action.-- A mix of pink and red granites.-- Maybe a quartzite or another rock type.-- Tumble to a Super-Bright Polish!-- We rate these stones as |

What Are "Red Beach Stones"?

If you like tumbled stones that are a bit larger than what is normally seen, then you will probably enjoy tumbling these red beach stones. That's why we like them.

Nearly all of these stones are composed of granite or similar igneous rock. A few stones of quartzite, ironstone or other rock types are occasionally found. Most produce a tumbled stone that is reddish in color (contains red as a primary or modifying hue).

The rough stones range in size from about one inch in diameter, up to a little over four inches in diameter - with the measurement taken across the stone's maximum dimension. We have been using them to make brightly polished tumbled stones - see the photograph above.

How We Tumble These Stones

Step 1: Coarse Grit / Rotary Tumbler

The goal of Step 1 was to resurface the stone, completely removing any weathering rind and grinding deep enough to remove surface blemishes. Since these stones are composed mostly of feldspar (Mohs Hardness of 6), nearly 3/16 inch can be removed in two weeks of tumbling.

We tumble these stones for two weeks straight in coarse grit (without stopping after one week for a grit change) in a Thumler's Model B rock tumbler. About 24 ounces of coarse grit was used. We filled the tumbler about 2/3 full of beach stones (about ten to twelve pounds of stones) and added just enough water to cover the rocks. No media was used.

When the coarse grit step is over and you have cleaned up your rocks, you might decide that they need a little more tumbling to remove blemishes and to smooth out irregularities in their shape. If that is the case, load the tumbler again with coarse grit and run them for another week or two. For rocks of this size, we find that another week or two of coarse grit rotary tumbling almost always improves their smoothness and shape - but they will be slightly smaller.

An alternative... pick out the rocks that need more tumbling and run them with your next batch. Move the rest of the rocks to the vibratory tumbler. We almost always do this if we have a lot of rocks to tumble.

Step 2: Medium Grit / Vibratory Tumbler

We then (depending upon the amount of rock we are tumbling) we switch to a Thumler's UV-10 vibratory tumbler or a Thumler's UV-18 vibratory tumbler. We find that vibratory tumblers produce a superior polish on large stones that are composed of minerals that cleave easily. These rocks are composed mainly of feldspar, a mineral with two directions of perfect cleavage. The continual pounding of the rocks in a rotary tumbler will produce bruises and broken feldspar grains in the surface of the stone.

The goal of the medium grit step is to smooth the surface of the stones. We place the cleaned stones in the bottom of an empty tumbler bowl, then add six tablespoons of medium grit (twelve tablespoons for a UV-18 tumbler), then add enough ceramic media of mixed sizes to bring the bowl up to a little less than its operating level. We then started the tumbler and slowly added enough water (one tablespoon at a time) to make the grit stick to the rocks.

Our goal is to have enough media in the bowl so that the stones circulate smoothly. At this point, we usually add a little more media to get the swirling load about 1/4 inch below the top of the center structure of the bowl. (IMPORTANT: Do not fill the bowl so high that the material in the bowl climbs up onto the washers and wing nut at the top of the center structure. If your load flows over the washer and wing nut, water and grit will flow down the center post hole and onto the motor). If you don't have smooth rotational tumbling action in the bowl, remove one of the rocks. We tumble the rocks in medium grit for three days, checking a few times per day and adding water as needed.

Step 3: Fine Grit / Vibratory Tumbler

We thoroughly clean the bowl, the lid, the media and the rocks and return them to the bowl. The goal of the fine grit step is to resurface the stones to a very smooth condition as preparation for the polishing step. We use six tablespoons of fine grit in a UV-10 and twelve tablespoons in a UV-18. Again, just enough water is added to make the grit stick to the rocks, and the tumbler is checked a few times per day, adding water if needed. Tumble in fine grit for two full days.

Step 3a: 30 Minute Burnish (optional but recommended)

We usually do a 30-minute burnishing step when the fine grit tumbling is complete and the rocks and media have been thoroughly washed. (Don't forget to scrub the foam lid pad of the tumbler barrel with a toothbrush to remove the rock mud that has splashed onto it.) The burnishing step is done to clean all of the fine grit from the small nooks and crevaces of the rocks and from the inside of the barrel. If you are not familiar with burnishing, you can find information about doing it with rotary and vibratory tumblers here.

Step 4: Polishing / Vibratory Tumbler

After the fine grit step we clean everything - the bowl, the lid, the media, the stones, and scrub the foam lid pad with a soft bristle toothbrush. Make sure every speck of grit has been cleaned off.

We now carefully place the stones in the bottom of the barrel, add six tablespoons of TXP polish to a UV-10 tumbler, or twelve tablespoons of TXP to a UV-18 tumbler. We then add all of the media and turn the tumbler on. Then very slowly, one tablespoon at a time, we add water. Be patient, slowly add water until the pieces of media are coated with a milky-colored slurry of TXP polish. If you get it too wet, add another tablespoon of polish.

We then place the lid on the tumbler and check it a few times per day, adding water if needed. On the second day, when you check the tumbler, pick out a couple stones, take them to the sink and rinse them thoroughly. Then dry them thoroughly. You should start seeing a little bit of light reflection from the surface of the stones. They are starting to polish. Keep checking the polish until it stops improving. That usually takes a minimum of two full days; three days is almost always enough. If you got a great polish, congratulations!

Step 4a: Another 30 Minute Burnish (optional but recommended)

We often do another 30-minute burnishing step when the polishing step is finished. This burnish is to throughly clean the polish out of any pores and fractures in the surface of the rocks, and to remove any polishing film that remains on the rock surface.

Contratulations! You should have some brightly-polished beach stones!

Red Beach Stones - Tumbling Properties * | |

| Marketing Name: | Red Beach Stones |

| Classification: | Rocks >> Igneous Rocks >> Granitic Igneous Rocks |

| Composition: | Dominantly feldspars, significant amounts of quartz, and minor amounts of amphibole and mica minerals. |

| Mohs Hardness: | Feldspars are the dominant minerals, and they have a Mohs hardness of 6. Amphiboles have a Mohs hardness of 5 to 6. For tumbling purposes, these rocks should be considered to have a hardness of 6. |

| Size: | The rocks being sold here range in size from one inch to four inches in diameter (measured across their maximum dimension). |

| Recommended Recipe: | We recommend using the tumbling recipe above. Additional guidance for tumbling these and other rocks that have been rounded by stream or beach action can be found in our article: Tumbling Stream- and Beach-Rounded Rocks. |

| Recommended Polish: | TXP aluminum oxide |

| Tips for Success: |

(1) These rocks are too large for small tumblers such as the Thumler's A-R1, the Lortone 3A and other tumblers with a barrel volume of less than about 1/2 gallon. Tumblers less than that size cannot tumble these large stones effectively. We have used a Thumler's Model B, a Lortone QT6 and a Lortone QT12 for tumbling rocks of this size.

(2) We always use a large rotary tumbler when tumbling large beach/river stones in coarse grit. We believe that a rotary tumbler is more effective than a vibratory tumbler for resurfacing rocks of this size. (3) We use a vibratory tumbler for the medium grit, fine grit, and polishing step. We use it for medium and fine grit because it is faster than rotary, and vibratory keeps these big stones from damaging one another. We use it for polishing because it is gentler on the stones and because it produces a superior polish. Additionally, with a vibratory tumbler, we can pull stones out at any time to see how the polish is developing. We polish until "it isn't getting any better". (4) It is not a good idea to include small rocks in a rotary tumbler barrel with large (over 2-inch diameter) rocks. Why? The large rocks will pound the daylights out of the smaller stones. Broken and bruised stones are often the result. Instead, we use ceramic media as a filler to cushion the large stones. |

| * Tumbling properties are for the stones being sold here. Stones from other sources may require a different procedure. | |

Customers also bought...

Large Ceramic Media

Small Ceramic Media

Standard Grit Kit